For your inquiries, email us :

inquiries@unifeeds.ph

The new UNIFEEDS 20MT/hr state of the art feed mill plant is driven by machineries with high end production efficiency. Its silos and steel structures for its warehouses can withstand wind velocity of 250 km/hr and an earthquake intensity seismic 8.3

SILO STORAGE : Four (4) units bulk storage space for grain materials (Corn, Wheat) with a capacity of 1,500 metric tons/unit. It is also equipped with temperature monitoring system and installed with computer controlled exhauster and blower that maintain the correct temperature and humidity.

RAW MATERIALS WAREHOUSE: Storage space for raw materials delivered in bags (Copra meal, Corn Gluten, Rice Bran, etc). With a storing capacity of 7,000-8,000 metric tons. Positioned nearest to the production area for easier handling and wastage.

MICRO DOSING SYSTEM : Fully automated batch weighing of individual micro-ingredients . This ensures accurate dosage of important micro ingredients in each batch of feeds being produced. The accurate dosing system ensures the consistency of the quality of each batch of feeds being mixed.

HYGINIZER : The longer retention time of the feeds in the Hygenizer render the pelleted feeds cleaner and free from bacteria, E. coli and salmonella.

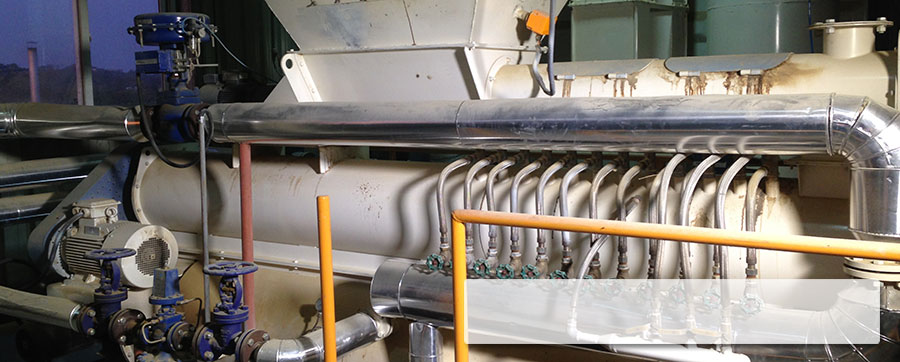

PELLETIZER : Computer controlled making the conditioning and pelleting process easier to monitor and maintain consistent conditioning of the feed . Feeds are precooked in a series of conditioner using steam up to 85 C.

BAGGING AREA : Automated weighing and filling system with digital display are used in bagging all feeds ensuring accuracy in the weight of each bag of feeds produced. Dual weigher makes the capacity higher without affecting accuracy. Capable of handling 25 and 50kgs bags

FINISHED GOODS WAREHOUSE : Our new warehouse is capable of storing 2,500 metric tons of finished goods equivalent to 50,000 bags of feeds at any given time. Close proximity to the production area minimizing the handling and transport of feeds.

UNIVERSAL FEED MILL CORPORATION recently inaugurated last May 3, 2014 its multimillion state of the art 20 metric ton Tayud Feed Mill Plant in Consolacion, Cebu. The new feedmill plant is supplied and built by Muyang China and is equipped with modernized control systems established by Siemens and driven by a machinery with high end production efficiency. The whole feedmill structure can withstand a wind velocity of 250kms/hr and earthquake intensity seismic 8. It has 4 units of 1,500 metric ton capacity for each silo as storage and a flat warehouse that has a capacity of 9,000 metric tons.

UNIVERSAL FEED MILL CORPORATION recently inaugurated last May 3, 2014 its multimillion state of the art 20 metric ton Tayud Feed Mill Plant in Consolacion, Cebu. The new feedmill plant is supplied and built by Muyang China and is equipped with modernized control systems established by Siemens and driven by a machinery with high end production efficiency. The whole feedmill structure can withstand a wind velocity of 250kms/hr and earthquake intensity seismic 8. It has 4 units of 1,500 metric ton capacity for each silo as storage and a flat warehouse that has a capacity of 9,000 metric tons.

continue reading

more videos

Scratch it to Win it Promo officially starts on May 01, 2018 to. Visit your nearest suking JM POULTRY & LIVESTOCK SUPPLY for a chance to win fabulous prizes.

Scratch it to Win it Promo officially starts on May 01, 2018 to. Visit your nearest suking JM POULTRY & LIVESTOCK SUPPLY for a chance to win fabulous prizes.

This promo is intended for CASH-END-USER CUSTOMERS (walk-in-takus-takus suki).

continue reading

Today, we're building a path toward becoming a new kind of company. Stocked with big ideas and bold solutions. Propelled by the pioneering spirits who find opportunity in change. Get to know our culture, our values, and what is like to be a part of our team.

Today, we're building a path toward becoming a new kind of company. Stocked with big ideas and bold solutions. Propelled by the pioneering spirits who find opportunity in change. Get to know our culture, our values, and what is like to be a part of our team.

Universal Feed Mill Corporation is all about bringing people together as an equal opportunity. Are you ready for the journey and grow with us?

continue reading